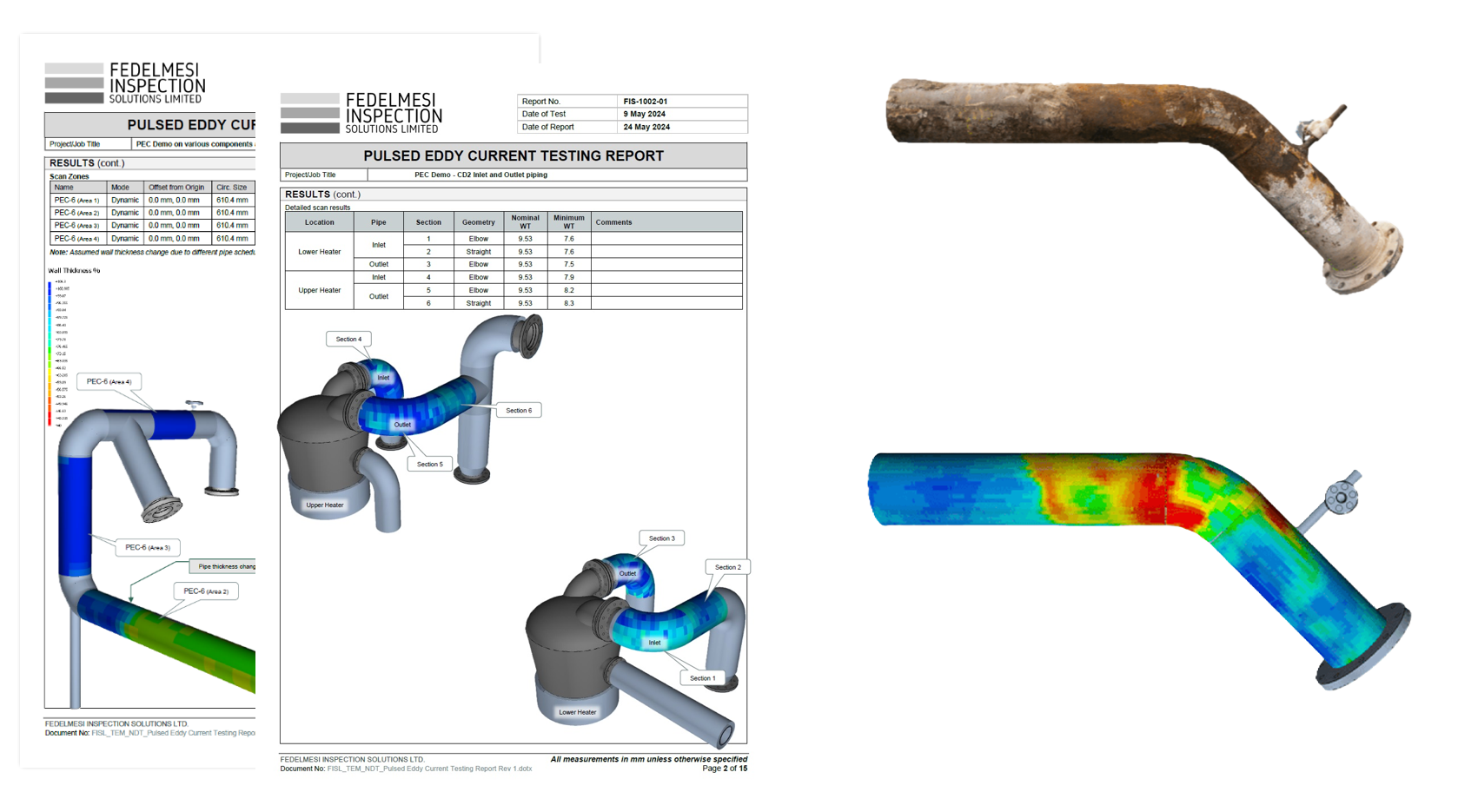

PULSED EDDY CURRENT (PEC)

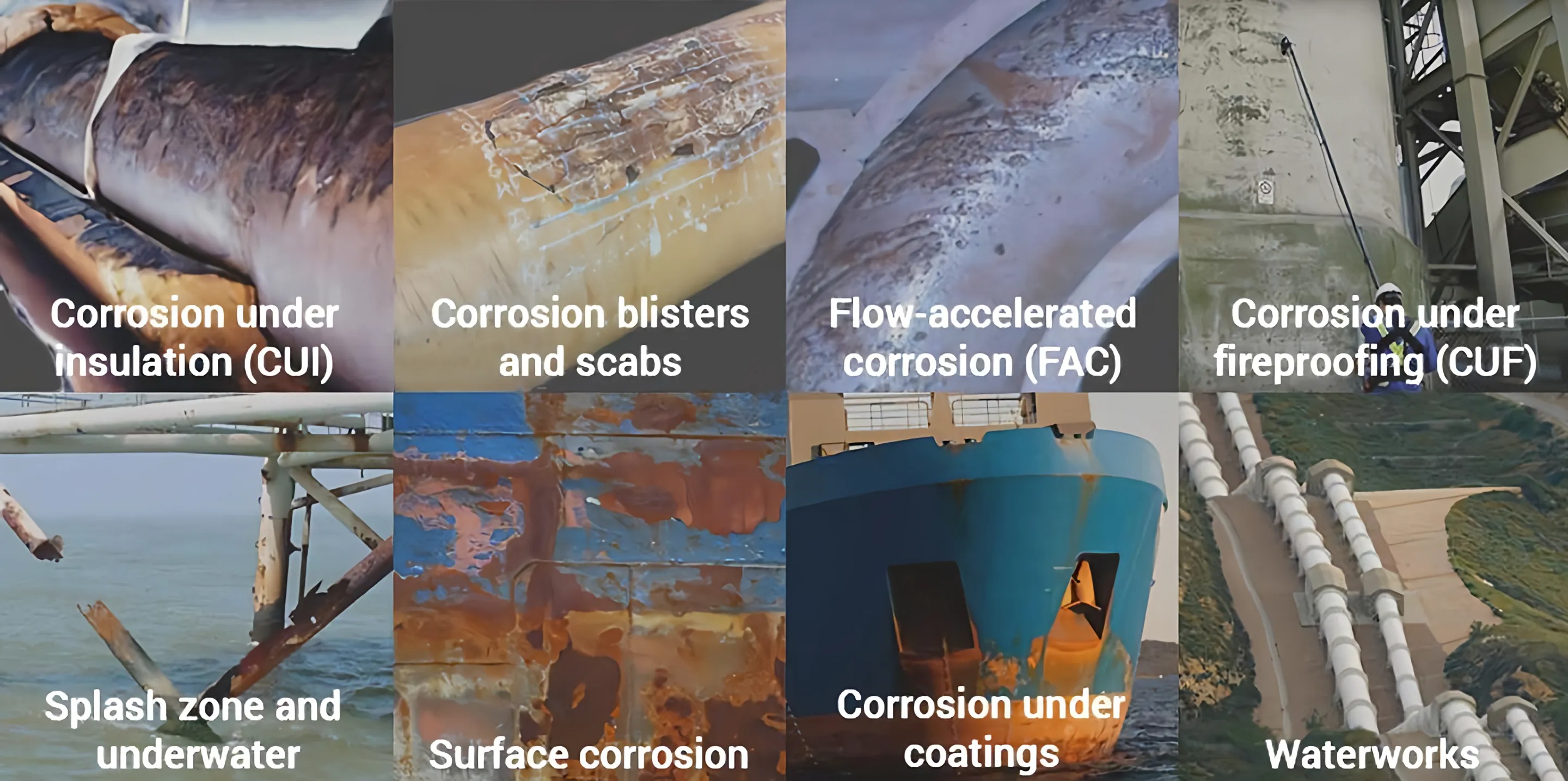

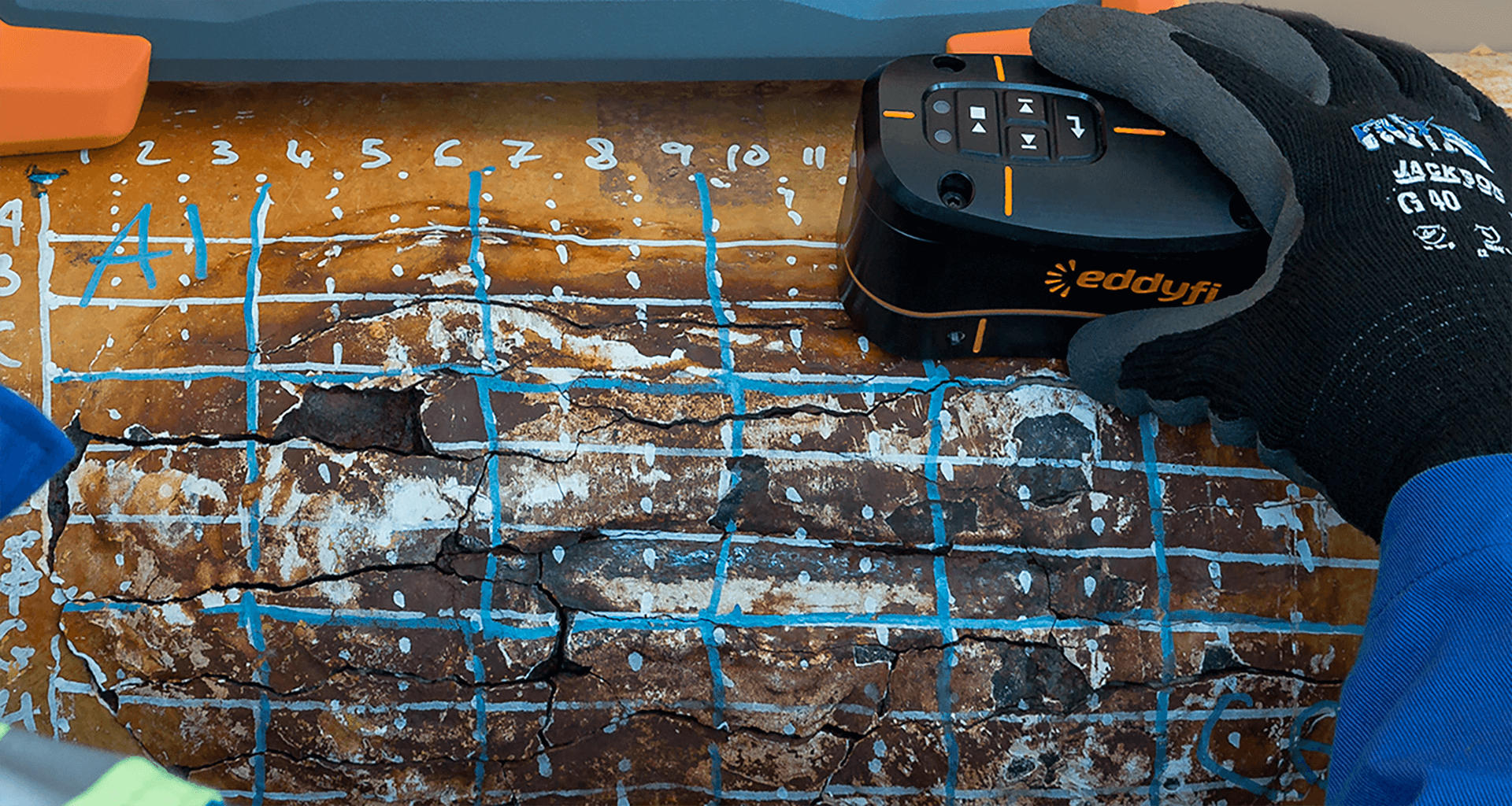

Pulsed Eddy Current (PEC) is an advanced electromagnetic inspection technique designed to detect wall loss in ferromagnetic materials like carbon steel and cast iron. It provides relative volumetric measurements converted into averaged thickness values, making it a powerful tool for non-intrusive asset inspections.